Ignition Prevention

WP8 will ensure significant reduction of the most probable ignition sources and improved management of fire hazards in ro-ro spaces, including provision for automatic screening and risk-based loading support.

WP08

Ignition Prevention

Today it is hard for a shipping company to know what kind of cargo is loaded onboard. It can be electrical components, food and cotton, goods that can have severe impact on each other in case of a fire outburst. But if goods could be analysed and stored in a safer way due to its characteristics it could minimize the damage in a ro-ro space and in the end on the whole ship. LASH FIRE work package 8 is developing a method to scan and analyse cargo for a safer placement and transportation.

The WP08 team have the following objectives on the agenda:

The work package deals with the significant reduction of the most probable ignition sources and an improved management of fire hazards in ro-ro spaces, including provision for automatic screening and risk-based loading support.

1. Development and demonstration of a technical solution for automatic screening of cargo to identify fire hazards and develop, utilize, and experimentally validate a digital logistics management tool featuring risk-based load planning.

2. Development of guidelines for safe electrical power connections in ro-ro spaces (refrigerated cargo units, charging of electrical vehicles, etc.), considering the design of electrical ship systems, equipment as well as operational procedures.

3. Determination of reaction to fire property requirements for non-regulated used new materials

The situation of today

A lot of cargo ships have sunk due to fires, with huge losses consequently. Many fires start in the ro-ro space that is loaded with different types of cargo. The shipping companies of today only takes dangerous goods into consideration when distributing the cargo along the decks. But 90% of fires spread due to standard goods. The characteristic of these standard cargos is not taken into consideration during the stowage process and, for example, placing electrical vehicles with batteries side by side with cotton goods, may have a catastrophic outcome.

Purpose of the WP08

The question is: how can these different materials and goods be analysed and organised better in the ro-ro space for the safest stowage? The purpose of the work performed in WP08 is to reduce the ignition of potential fire in cargo due to electrical, mechanical, overheating and other causes. The impact of WP08 is a minimised risk for both ship and crew (and passengers in ro-pax ships).

Ignition prevention via drones

The method

WP08 analyse the cargo and all type of characteristics of the different goods. This job is done through some different tools and technologies.

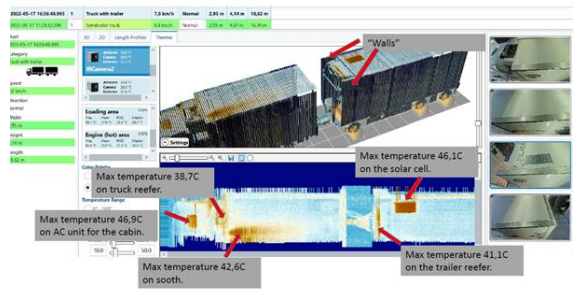

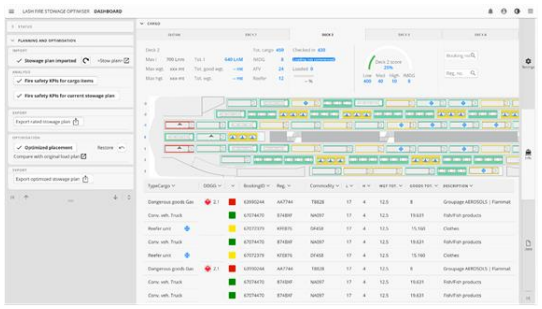

The visualisation tool and arc of sensors help the operator to see and scan the cargo. The cargo gets an analysis regarding relevent features such as temperature. When the components inside one transport unit are scanned, and once it has been analyzed and verified that it is safe, it is loaded adding a fire management perspective to the stowage process to reduce ignition. Specific locations of cargo units is suggested by the Stowage Planning Tool, which takes into consideration a big amount of data from reports of accidents and the cargo risk assessment.

The progress of WP08

Status, June 2021

By the end of 2021 the team will start testing the system. Up to now (2 years), the technology has been developed and laboratory tests have been conducted. Unfortunately, Covid19 has led to some delays and has made the work hard as it must also be tested on site.

Action 8-A Automatic screening and management of cargo fire hazards

Development of 4 tools: Arc of sensors, drones, visualisation tool and stowage planning tool. The development of these tools is the core of this action. The working of finishing these tools are ongoing and more sensors are being added to the arc of sensor etc. Development and implementation of the Stowage Planning Tool is ongoing as well.

Photos from a visit to the Balearia ships in the port of Valencia. The pictures show how the cars are loaded inside the ships and the manoeuvres in the terminal. The purpose of the visit was to learn about the loading manoeuvres on the ship and terminal with the aim of collecting data that will allow us to make the stowage planning tool and later the simulation of the terminal.

Action 8-B Guidelines and solutions for safe electrical connections

This action focuses on electrical vehicles and cargo including parts that must be plugged into the storage spaces such as reefer units. Up to now a routine has been developed on how to proceed with this type of cargo and how electrical risk can be reduced. Rules and Guidelines for the best option will be further developed analysing incident reports.

Action 8-C

This action started in March 2021. It can be seen as the most innovative action among the tasks focusing on new materials that can reduce ignition and spread of fire. The task is not simple as there do not exist any regulations for materials and how they react to fire. The results from this study is considered important for the shipping sector by LASH FIRE.

Status, November 2022

Action 8-A Automatic screening and management of cargo fire hazards

A successful installation of the LASHFIRE- VHD (vehicle hot-spot detector) in the maritime environment was completed at the Majnabbe terminal (Stena terminal). The 2022 was mainly used for collecting vehicle files from trucks with cooling units. SICK has used this vehicles files for training of the system to detect overheated cooling units. here will be probably be more training of the algorithm in the future to further improve the hot spot detection on cooling units but this is a first big step.

The so-called Stowage Planning Tool supports the corresponding process through a set of software components composed of a cargo distribution algorithm including fire hazard management and an HCD (Human-Centered Design) visual interface enabling end users to interact with.

A concept for usage of a drone Automated Guided Vehicle (AGV) is under development, the AGV will use IR/thermal sensors and the operational envelope is as low as 12 cm in height for the LASHFIRE tests.

Action 8-B Guidelines and solutions for safe electrical connections

This action focuses on safe electrical connections through the protection and design of the circuit. Technical discussions on the subject of balancing the cost of improvements versus the frequency of recorded incidents have been held, to the perceived benefit of the solution being finalized.

As a smart and a robust system, the proposed solution is designed to predict possible fires or extreme electrical conditions using artificial intelligence. With the knowledge of ideal behaviour of electrical parameters of the loads, the constantly monitored data can be used as a comparison and a model can be built and trained to study the differences

Also, based on analysed incidents and near miss scenarios, certain operational changes have been proposed. Space for test bed setup finalized and installation starting

Last October, Vasudev Ramachandra from RISE presented Safe connections of reefer units and charging of electric cars at CFIS2022.

Action 8-C Fire requirements for new ro-ro space materials

The tasks of this action are on-going and investigation of regulations and test standards related to surface materials in ro-ro spaces have been finalized so far.